|

Author

|

Message |

|

|

Posted: Sat Apr 02, 2011 11:59 am Posted: Sat Apr 02, 2011 11:59 am |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

|

|

|

|

|

|

|

|

Posted: Sat Apr 02, 2011 12:05 pm Posted: Sat Apr 02, 2011 12:05 pm |

|

|

|

|

Joined: Feb 07, 2010

Posts: 3085

Trade Rating: +12

Location: Essex

|

|

Looking good.... it looks very nice at pace.... would like to see more of this

| |  |

|

|

|

|

|

|

|

|

|

Posted: Sat Apr 02, 2011 12:07 pm Posted: Sat Apr 02, 2011 12:07 pm |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

|

|

|

|

|

|

|

|

Posted: Sat Apr 02, 2011 12:09 pm Posted: Sat Apr 02, 2011 12:09 pm |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

|

|

|

|

|

|

|

|

Posted: Sat Apr 02, 2011 3:48 pm Posted: Sat Apr 02, 2011 3:48 pm |

|

|

|

|

Joined: Feb 07, 2010

Posts: 2874

Trade Rating: +4

Location: Chichester, Sussex

|

|

A 413bhp 106

Any links to the build on that?

| |  |

|

|

|

|

|

|

|

|

|

Posted: Sat Apr 02, 2011 8:27 pm Posted: Sat Apr 02, 2011 8:27 pm |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

|

|

|

|

|

|

|

|

Posted: Sun Apr 03, 2011 11:01 am Posted: Sun Apr 03, 2011 11:01 am |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

|

|

|

|

|

|

|

|

Posted: Sun Apr 03, 2011 11:28 am Posted: Sun Apr 03, 2011 11:28 am |

|

|

|

|

Joined: Feb 07, 2010

Posts: 3085

Trade Rating: +12

Location: Essex

|

|

Nice video there..... having read the thread on the 106 build I can see why he got panicky with all that smoke.... glad it was only an oil pipe.... your car seems to run very well.... nice job

| |  |

|

|

|

|

|

|

|

|

|

Posted: Sun Apr 03, 2011 11:50 am Posted: Sun Apr 03, 2011 11:50 am |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

| macj wrote: |

| Nice video there..... having read the thread on the 106 build I can see why he got panicky with all that smoke.... glad it was only an oil pipe.... your car seems to run very well.... nice job |

Yeah the oil pipe from the sandwichplate to the oil cooler was broken and spilled al the oil, but no damage to the engine.

My car is runnig great, the combination of sachs multipuk performance clutch and Oem pressure plate is still not what it should be, but for now it is what it is. I'm first going tu upgrade the suspension with SuperPro Polyurethane bushings, Whiteline front and rear anti-rollbars and Ultra Racing H-brace.

| |  |

|

|

|

|

|

|

|

|

|

Posted: Sun Apr 03, 2011 11:58 am Posted: Sun Apr 03, 2011 11:58 am |

|

|

|

|

Joined: Feb 07, 2010

Posts: 3085

Trade Rating: +12

Location: Essex

|

|

It does sound like you have a slipping clutch, But I thought maybe it was tyre spin-up..... do you have a LSD fitted?, I found that was one of the first modifications I made after first test. I now have new gear ratios and will be setting up suspension options at the next test. I currently have Gaz suspension all round which is custom made to my spec...

| |  |

|

|

|

|

|

|

|

|

|

Posted: Sun Apr 03, 2011 12:05 pm Posted: Sun Apr 03, 2011 12:05 pm |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

I've decieded to as less possible on the car this summer, except driving it. I've spent almost two years building it and it's about time i started driving it. Up coming winter the car will get a repaint and will get wider wheel arches and a new transmision with Quaife LSD and Sachs high performance pressure plate.

I'm currently driving with D2 shocks with camber adjustments. Not the best you can buy, but a fair price to quality ratio. The rest of the suspension is still completly stock. With the upcomming suspension mods the car should be handeling a lot better.

| |  |

|

|

|

|

|

|

|

|

|

Posted: Wed May 18, 2011 7:50 pm Posted: Wed May 18, 2011 7:50 pm |

|

|

|

|

Joined: Oct 20, 2010

Posts: 15

Trade Rating: 0

Location: Australia

|

|

Hi White_Noise,

Could you tell me what was involved in pairing the Honda TB with the GTI 180 Intake manifold. I've come across a cheap GTI180 inlet manifold, and would love a detailed on response, on what needs to be done.

PS: Its going on a GTI138HP

| |  |

|

|

|

| |  |

| 2003 Peugeot 206 GTI 138HP

Custom Intake using standard airbox

Straight through perfromance muffler

Griffith Engineering Quick Shift

Group N uprated gear linkages | |

| |  |

|

|

|

|

|

|

|

Posted: Thu May 19, 2011 3:26 am Posted: Thu May 19, 2011 3:26 am |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

You need to portmatch the cilinderhead in order to make the 180 inlet work on rhe 138. you have to fabricate a flange underneath the inlet for the steppermotor and in order to make honda tb work you have to drill new tap holes in the 180 inlet and completly modify the honda tb to work with al the peugeot tb sensors. And you also have to make a new tb cable mount. Eventually for a non turbo setup yo much effort for to little power gain

| |  |

|

|

|

|

|

|

|

|

|

Posted: Fri May 20, 2011 2:27 am Posted: Fri May 20, 2011 2:27 am |

|

|

|

|

Joined: Feb 08, 2010

Posts: 901

Trade Rating: +1

Location: Istanbul / Turkey

|

|

| track370z wrote: |

Hi White_Noise,

Could you tell me what was involved in pairing the Honda TB with the GTI 180 Intake manifold. I've come across a cheap GTI180 inlet manifold, and would love a detailed on response, on what needs to be done.

PS: Its going on a GTI138HP |

Hi. Please look our project page. Your questions answers is there.

206info.co.uk/Forums/v...25312.html

| |  |

|

|

|

| |  |

| 2005 206 RC RED

Bilstein B14 Coilover / Brembo 4 Pot Front 330x28 - Rear 325x8 / Quaife ATB Limited Slip Diff / Janspeed Catback

Lot's of CNC machined customs pars.  | |

| |  |

|

|

|

|

|

|

|

Posted: Mon May 23, 2011 3:54 pm Posted: Mon May 23, 2011 3:54 pm |

|

|

|

|

Joined: Mar 08, 2010

Posts: 91

Trade Rating: 0

Location: Netherlands

|

|

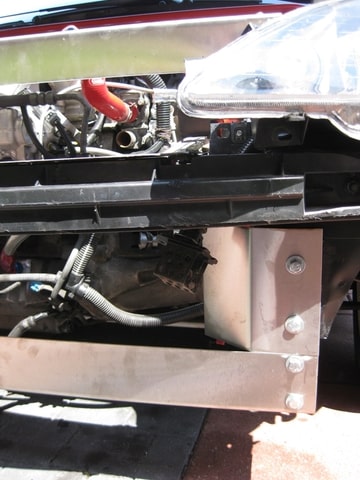

After several modifications on the stock the coolingsystem there was still a lack of sufficient cooling. So i've decided to completly chop the the stock radiatorhousing and design a new one out of stainless steel to fit a full size Mitsubishi Lancer Evo 5 Raditor. This radiator is twice as thick as the oem peugeot 206 gti radiator and also 100mm longer, so it has twice as much cooling capacity.

First i've removed the old plastick fanshroud and made a new upper horizontal beam out of 2mm stainless steel and then cut out the lower horizontal beam and welded in two new vertical box sections on boths sides in order to make the bigger radiator fit.

Relocated the fan relais in to the bumper beam

Lower horizontal beam boledt in to place also made out of 2mm stainless steel bent to a 90 degree angle.

Covered the sides with stainless steel sheets and bent to 45 degree to force the air into the radiator

Sheet of stainless steel to cover up the relais and extra support for the intercooler mounts.

New radiator fitted in new frame

Dubble 12inch slimfans for extra cooling, these can be turned on manully from inside the car by switch

Intercooler installed

Still had to find a new place for the oil cooler, so i've made a new supprt bracket out of stainless steel bent to 90 degree angle.

Oil cooler installed on new bracket

Intercooler back in place and now i've just have to wait for all the new fittings and stainles steel braided hoses for the oil cooler and were ready to race again.

| |  |

|

|

|

|

|

|

|

|