|

Author

|

Message |

|

|

Posted: Tue May 21, 2013 8:00 am Posted: Tue May 21, 2013 8:00 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

So I took my 1.9D basic 206 and made it alot better in terms of power.

I like the fact of the XUD9 being a simple engine to modify and maintain and I like the 206. So over a few months of trail and error, 6 or 7 times fitting and removing the engine from the bay, much bad language and numerous trips to breaker yards we had the machine driving under its own power.

The original spec:

Peugeot 206 1.9L D

DW8 1.9 Donkey engine (69 bhp?)

No Positive Manifold Pressure

Hydraulic Clutch

46,000 miles (car and engine)

247mm Front Brakes

Steelies

Dent in Door

Spec to date:

Peugeot 206 1.9 Turbo Diesel

XUD9TE (D8B) Engine (circa 120bhp (at a guess))

26 PSi on a K14

Pull Clutch CableSetup

FMIC

91,000 miles (engine)

283mm Front Brakes

Boost Gauge

16" Nimrods

Dent in door now sorted

Engine came from a 1995 Xantia and was at standard power but after a few tweaks and help from the cornish derv doctor (best friend from college) the car has found a new lease of life.

ALL modifications (including engine change and power levels) be been made known to the relevant parties. Namely DVLA and Insurance.

I have more plans for it including another engine transplant (XUD9 still) for some more power but this is the preliminary test to see if it could be done. (Wasn't as easy as I thought originally)

It is no oil painting (due to being worked on in a barn) but its tidy and standard looking (ish).

Anyways Pictures...

The night I got the Car

Original DW8 Engine

The day it drove out of the shed on its new heart

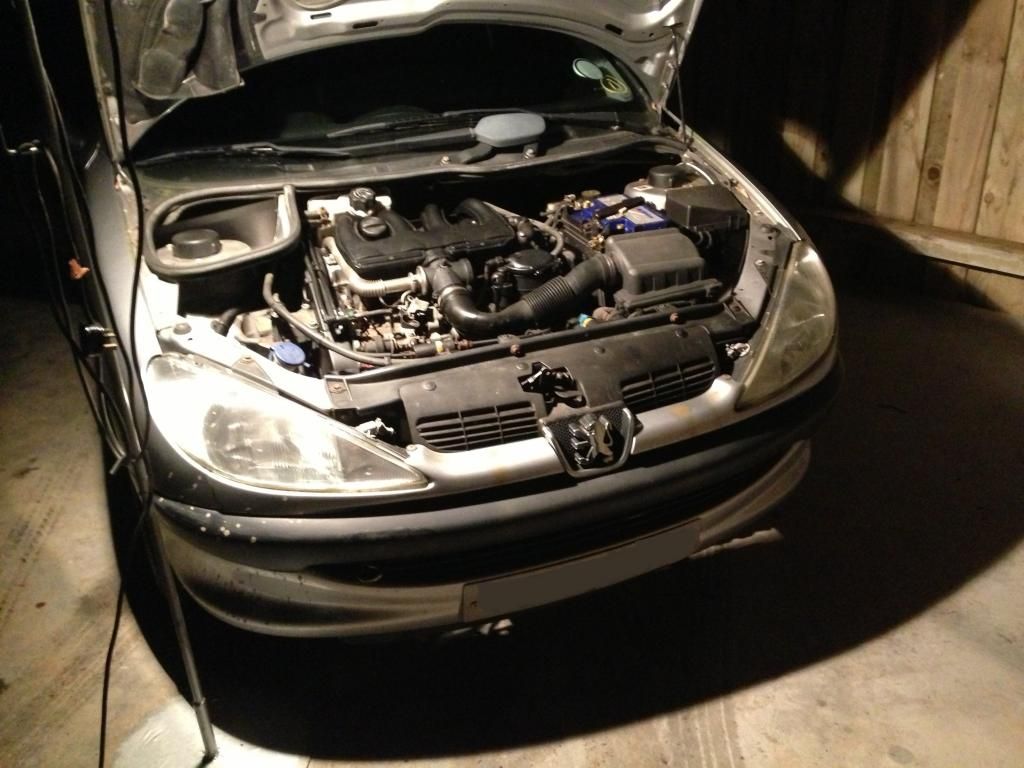

The engine bay with the new motor

Unfortunately no recent one of how the car looks at the moment due to it being back in the shed. I do have more of the actual build, so I can put them up once I sorted through.

Comments welcomed...good and bad.

Thanks for Looking

| |  |

|

|

|

Last edited by southwestchap on Mon Feb 10, 2014 6:00 am; edited 2 times in total

|

|

|

|

|

|

Posted: Wed Jun 19, 2013 4:31 am Posted: Wed Jun 19, 2013 4:31 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

So the engine came out again on the weekend

and got replaced with the second XUD engine I have (yes its green just because I got bored with a paint brush one day)

and now fitted

Had some help from a few friends to get everything built up and fitted

Spec now:

XUD9TE (D8A)

GT22 VNT Turbo

MBC

Bosch Pump (Stripped, Rebuilt, Governor Modification, LDA Pin Grind, 11mm Head)

Injector Pressure Ramped Up

ARP Head Studs

Bigger Exhaust Downpipe

306 HDi Gearbox

206/207 OEM FMIC

Not quite fully back together yet as the PAS setup is being re-routed and also the Intercooler pipework is changing.

| |  |

|

|

|

|

|

|

|

|

Posted: Thu Jun 20, 2013 8:57 pm Posted: Thu Jun 20, 2013 8:57 pm |

|

|

|

|

Joined: Sep 14, 2012

Posts: 169

Trade Rating: 0

Location: Northern Ireland

|

|

Im considering dropping in a 1.9TD from a 306. I currently have a 1.4 hdi. Is it worth it?

| |  |

|

|

|

|

|

|

|

|

Posted: Fri Jun 21, 2013 7:02 am Posted: Fri Jun 21, 2013 7:02 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

I went ahead with it due to liking the simplicity of the XUD and also liking the 206 setup so just putting the two together.

Originally I thought it would be easy but the thing decided to fight along most of the way.

2 engine mounts need to be modified, drive shafts needed to be altered (saying that just use the 206 DW10 gearbox and clutch setup and you'll be fine)

I drove the first engine over 2000 miles, 1000 which were when the pump and turbo were opened up, without any issues at all.

if you had the engine and exhaust off the 306 there isn't a lot that needs to be changed.

Only issue I would see you having is the loom wiring issues for the dash, as the HDi is multiplexed therefore you will have a lot of redundant wiring.

| |  |

|

|

|

|

|

|

|

|

Posted: Thu Aug 29, 2013 3:09 pm Posted: Thu Aug 29, 2013 3:09 pm |

|

|

|

|

Joined: Feb 07, 2010

Posts: 7094

Trade Rating: +11

Location: Suffolk

|

|

Any news on this project as it looks rather interesting. ...

| |  |

|

|

|

| |  |

| Team Impossible Possible

The only way of finding the limits of the possible is by going beyond them into the impossible - Arthur C. Clarke

Forged 1.6 Turbo

Click to see more

144Bhp @ 7PSi - 193.9Bhp @ 13psi

206 Gti Race Car

Click to see more

For all Race/Track Preparation, Feel Free to PM Me!

Whether its for a custom ratio gearbox or track-day alignment, I can help! | |

| |  |

|

|

|

|

|

|

Posted: Fri Aug 30, 2013 8:01 am Posted: Fri Aug 30, 2013 8:01 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

Yea a bit has happened...read on...

Well from when the cornish lads helped fit the engine I loosely built the rest up and took it for a quick drive. Honestly couldn’t see what the fuss was about for the VNT lark. Smokey, laggy, pinning the 30 psi gauge....I knew there were issues. The vanes weren’t opening. Basically the VAC can didn’t like to work the other way around so couldn’t do much with the engine in the car so out it came again. Was able to tidy a few things up then, namely piping. Fitted a better can and started to lift the engine back in.

Had the machine man make me up a tall engine mount bolt. For when we slotted the drivers mount forward for clearance.

Was toying with wheels

Bit tight in my opinion

New water pipe made

Also fitted some cheapy coilovers

And fitted, even managed to save the droplink.

Engine back in and fitted the Red engine mount

Severe lack of photos then. But got the car back together on its wheels

Hellish problems with getting the vanes to open with the boost still. In the end found out it was the MBC being too closed up, but the actual spring inside had coiled up. Sorted that and went for a drive. Was really pleased to see the gauge stop at 15psi and OH MY GOD it was an absolute ANIMAL.

Upped the boost to a safe 20psi and it was insane...well coming from a K14 which you literally had to strangle the sod to keep ‘er blowin. This is whole different drive. From the moment your foot is in the floor, the power is there and a definite huge increase in torque. By the way, this is still with my hellish restrictive inlet. When I sort that out, I swear something is going to break (though I don’t drive hard all the time). Also when you come to a hill, no need to drop a cog, as long as you don’t ‘bog’ the fuel in, the turbo comes into play and it will literally pull without breaking a sweat.

All this happened the week of the FCS weekend so still not actually road tested the thing for more than a couple of miles. Went ahead and fitted (well lashed up) my gauges. Only cheapies that I have had for a while from previous car’s seem to work ok though.

Fitted all the interior in and drove around Exeter, filled up with fuel and drove the long way home. 20 miles on the engine now so I hoped that would be enough as FCS was only a couple days away and still had a few things to sort out.

The morning before we left

After a bit of thought on lowering (which I thought I would never do) I decided to drop the rear end a tad, and I have also fitted the coilovers so it would be rude not to.

Never lowered anything before I seeked out the help from the cornish lad. So drove off down there on Sunday and backed the car into the workshop.

Wheels off and started wire brushing the shiz out of everything and spraying all threads with penetrating fluid.

Anti-roll bar came out relatively easy but we faced the issue of the lower shock absorber nut and bolt. The grinder came into play.

Managed to get the eccentric washers removed and got the bearing puller out and setup. Got the trailing arm to then slide off fairly well.

Notice the quad wheel used to prop the trailing arm up.

On inspection of the bearings they were all still complete and the beam itself had no wear in it which was a bonus.

Got the arm propped up

The torsion bar would not release on the drivers side, we even removed the whole trailing arm which meant taking the handbrake cable off and disconnecting the brake line. The inner bearing did decide to fall apart due to having to smash the arm off with the hammer (puller wouldn’t work on driver side)

Annoying the torsion bar still didn’t want to let go despite using a ‘farm spec’ sledgehammer on it.

Started putting it back together and with the other torsion bar in we still managed to lower it the desired amount of 30mm.

Connect all the brakes back up and put the wheels on and this is how it sat.

And one of the helping hands.

With the front dropped a little more

So really just been driving the thing as I've had a few other things that I 've been sorting. Soon be time to get it back in the shed. Still puts a smile on my face when I drive it. Especially going from a 1.4HDi.

Future plans are:

To sort that awful inlet

Bigger Intercooler

Build a bigger exhaust

Sort the Driver’s side window

General tidying

The Xantia engine that came out has plans for a rebuild with bigger rods, maybe a bit of porting, and a 10mm pump. The 11mm is a little over kill as it will coal to buggery if you're not considerate. This will be a long term thing as I have other things that need to be worked on first.

| |  |

|

|

|

|

|

|

|

|

Posted: Fri Aug 30, 2013 11:32 am Posted: Fri Aug 30, 2013 11:32 am |

|

|

|

|

Joined: Feb 08, 2010

Posts: 7047

Trade Rating: +5

Location: In the garage

|

|

Nice to see somebody doing some proper work!

| |  |

|

|

|

| |  |

| 2001 GTi 138, Bilstein Sprint dampers, H&R springs, 21mm Peugeot Sport torsion bars, 22mm rear ARB, Peugeot Sport Group A wishbones, 283mm discs, Goodridge stainless hoses, Maniflow 304 grade 4-2-1 2.5" manifold and system, 200 cell cat, Richard Longman head, 45mm Jenvey throttle bodies, 9.5mm TB spacers, 90mm air horns, Jenvey throttle linkage, Jenvey fuel rail, Aeromotive and Goodridge fuel fittings and braided hose, ITG sausage filter, Radtec custom radiator, Piper Ultimate Road cams, Piper vernier pulleys, Omex 600 ECU, Omex bespoke race loom. Saxo electric PAS pump, Vibra Technics engine mounts. Samco coolant hoses, TTV steel flywheel, 4.76 final drive ratio, 307 CC 180 ratios. 2019 BMW 530i. 2017 Mercedes C300 convertible. | |

| |  |

|

|

|

|

|

|

Posted: Fri Aug 30, 2013 1:19 pm Posted: Fri Aug 30, 2013 1:19 pm |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

| Edward wrote: |

| Nice to see somebody doing some proper work! |

Cheers :-D, lot of work, time & bad language went into it to get it where its at today.

| |  |

|

|

|

|

|

|

|

|

Posted: Fri Aug 30, 2013 1:29 pm Posted: Fri Aug 30, 2013 1:29 pm |

|

|

|

|

Joined: Nov 27, 2010

Posts: 11522

Trade Rating: +10

Location: What's it to you? ? ?

|

|

What happened to the 405 MI16 5 spoke alloys then?

| |  |

|

|

|

| |  |

| Toyota C-HR GR Sport 2.0 Hybrid with JBL & Alcantara packs. | |

| |  |

|

|

|

|

|

|

Posted: Fri Aug 30, 2013 4:04 pm Posted: Fri Aug 30, 2013 4:04 pm |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

| MrBSI wrote: |

| What happened to the 405 MI16 5 spoke alloys then? |

Yeah I still have them, need to fit a couple tyres on them and was going to fit them to my hdi for something different. (Thats if the offset allows me). Wasn't really keen on putting them on the idi 206 as you can see from the picture, the clearence wasn't very much.

| |  |

|

|

|

|

|

|

|

|

Posted: Sat Aug 31, 2013 3:53 am Posted: Sat Aug 31, 2013 3:53 am |

|

|

|

|

Joined: Nov 28, 2011

Posts: 411

Trade Rating: +1

Location: sunny stoke

|

|

is this darren lobbs place where the work is being done?

| |  |

|

|

|

|

|

|

|

|

Posted: Sat Aug 31, 2013 8:24 am Posted: Sat Aug 31, 2013 8:24 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

| HDI90 wrote: |

| is this darren lobbs place where the work is being done? |

For the lowering yes, i took a trip down as he had bearing pullers and such.the rest was done in at mine.

| |  |

|

|

|

|

|

|

|

|

Posted: Fri Jan 03, 2014 7:07 am Posted: Fri Jan 03, 2014 7:07 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

So bit of an update

Engine Back out

Fresh Clutch - 4 paddle unsprung

Collection of exhausts - recently realised how restrictive the things are...

But this is the one to be used 2.5" all the way

Fresh downpipe and flexi

Going back together

With a New Intercooler

Mounted top and bottom

Chocked up the top mount - also using a powerflex lower mount and a xantia gearbox one. Pretty solid now for the time being

Boost and EGT gauges

Also fitted an EMP gauge but no pictures of that

Backbox is a little 'in your face' and the first few trips were a little smokey but got the tuning under control now

This is the original engine going to be rebuilt

and decided to fit a 3" downward tip - well cut up an old lorry exhaust for the bend and a friend helped fit it.

Since though, I have changed the fuel pump to a low milage, 10mm modified bosch with a stronger gov mod to keep the fuel in to 5k.

| |  |

|

|

|

|

|

|

|

|

Posted: Sun Jan 05, 2014 2:18 pm Posted: Sun Jan 05, 2014 2:18 pm |

|

|

|

|

Joined: Mar 03, 2010

Posts: 2636

Trade Rating: +11

Location: Black Country Ay I

|

|

Proper project  I like it! I like it!

| |  |

|

|

|

|

|

|

|

|

Posted: Mon Jan 06, 2014 6:57 am Posted: Mon Jan 06, 2014 6:57 am |

|

|

|

|

Joined: Feb 16, 2010

Posts: 440

Trade Rating: +2

Location: Devon

|

|

| Andrew wrote: |

Proper project  I like it! I like it! |

Cheers.

| |  |

|

|

|

|

|

|

|